Laser Cutting

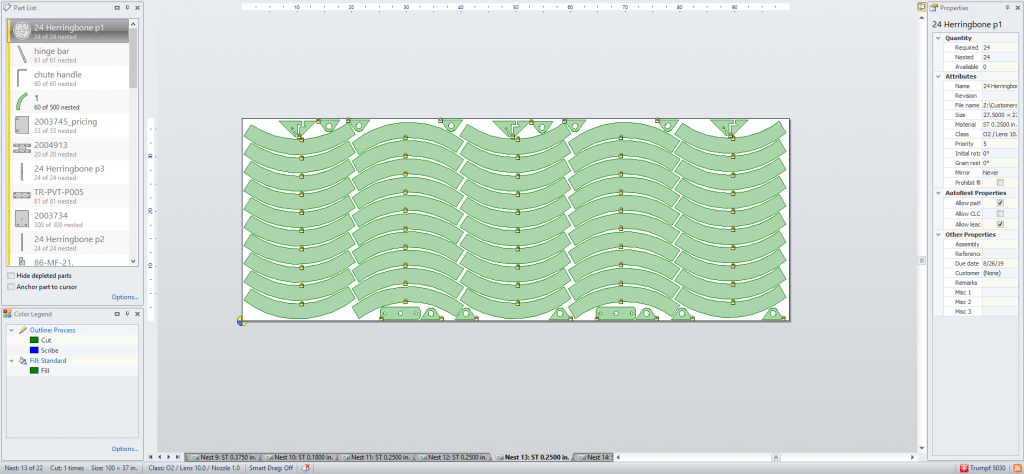

With our inhouse fiber laser machines we are able to give our customers the parts they need whether it is a small job or a large ongoing project that requires many parts from many thicknesses.

Grey Metals has recently installed a 20KW Fiber laser cutting system that will effectively cut up to 3/4 inch mild steel with nitrogen, removing the need for oxide removal before welding or paint in many cases.

With a 20 KW system we are able to effectively cut materials up to 50MM in thickness. Some of the most common being Mild steel, Stainless and Aluminum.

With the large format bed size parts up to 2 meters by 4 meters can be cut.

Brake Press Forming

With laser cutting and Pressbrake forming going hand in hand we have Pressbrakes and tooling available for all forming needs. Having newer model Pressbrakes and precision ground tooling results in an ability to produce even the most complex parts and high volume products effectively.

Tube Laser Cutting

3D CNC tube lasers have the ability to cost effectively and precisely cut any holes or complex shapes and ends into tubing ,angle ,or even channel

Welding

Welding being one of the first things we started with, we now work with a variety of different metals ranging from plain carbon steel and aluminum to stainless. Throughout the years, we have acquired manufacturing equipment that allows us to fabricate, weld and assemble most anything at our facility. We incorporate both Manual and Robotic MIG welding, TIG and Spot welding in our production welding facility.

Coatings

Grey Metals offers a complete range of coatings for your parts. Including powder coating, Electro-plating and galvanizing.